United States Patent and Trademark Office granted a patent (US 9,610,714 B2) to Samara National Research University (SU).

The key factor in high assessment of the innovation in the United States became the use of unique damping material – metal rubber (MR) developed by SU scientists and produced at the university laboratories.

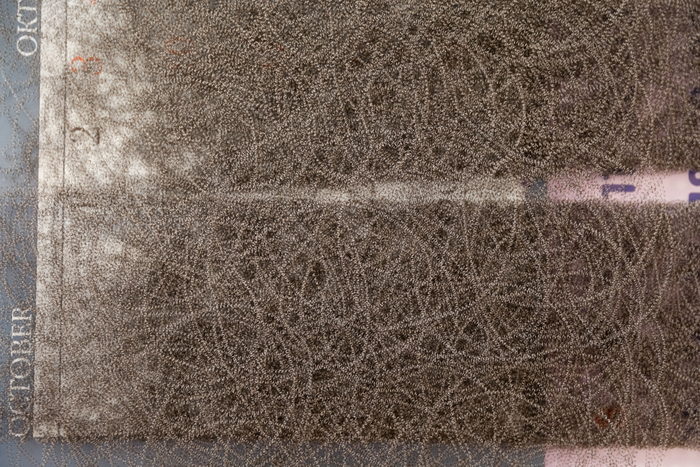

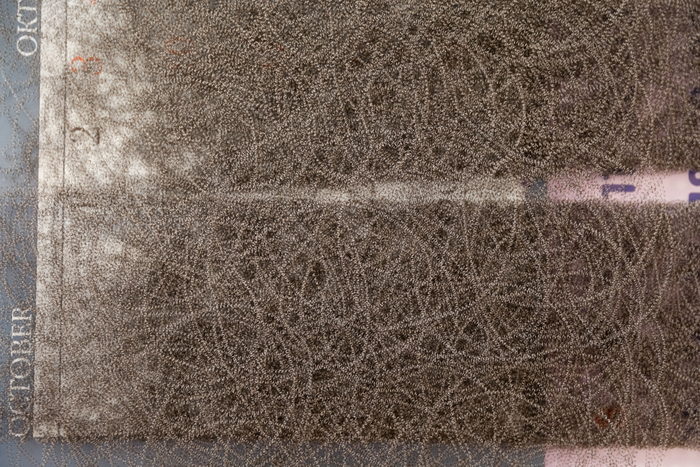

Unlike elastomers the material has high damping characteristics, is resistant to corrosion, extreme temperatures, high vacuum, damp, radiation and other stressed conditions. Metal rubber material gets such characteristics due to a special technology of netting and pressing of spiral metal threads of different diameters.

Dampers on the basis of metal rubber material highly exceed known Russian and foreign analogues in reliability.

Due to the lucky combination of rare characteristics vibroinsulators of MR are actively used in Russian space engineering, predominantly for prevention of devastating influence of extreme vibration and impact loads on air-borne equipment.

Russian bootlace vibroinsulators play a special part among their analogues due to the simplicity and manufacturability. They have small size and weight with high static strength. Moreover, with mass production the manufacturing cost of elastoporous bootlace vibroinsulators is not high.

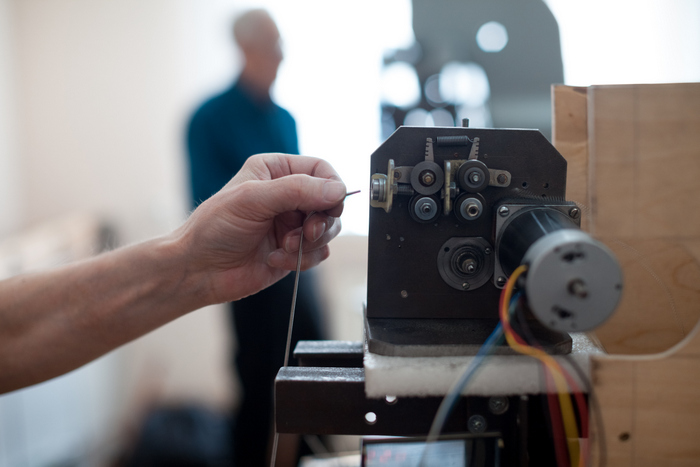

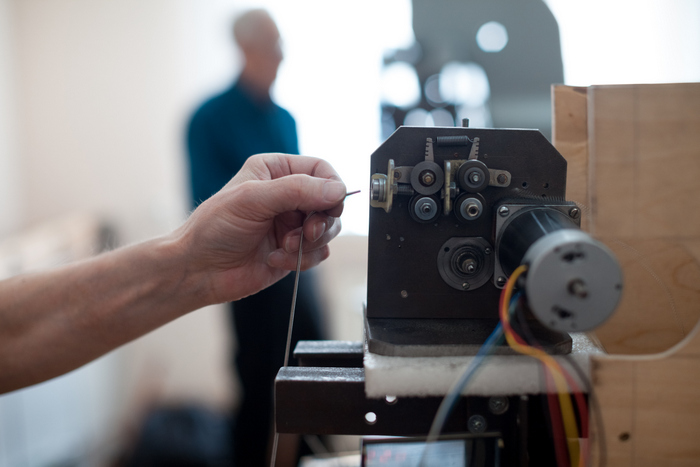

Understanding high potential of metal rubber material and use of bootlace vibroinsulators and filtering elements Samara University scientists concentrated their efforts on the improvement of the production means of thin-walled elastoporous elements of metal rubber. This innovation technology was acknowledged abroad.

The aim of the authors’ group of Samara University developers (Danila Davydov, Gennadii Lazutkin, Petr Bondarchuk, Alexander Ermakov and Tatiana Volkova) was to create a means of production of thin-walled elastoporous barrels with the enhanced characteristics of reliability. As a result they succeeded in the development of a new technological process which allows manufacturing a wide range of metal rubber thin-walled elements of high reliability on a production basis.

The spheres of application of the products of MR material are really diverse: mechanical engineering, oil industry (drilling rigs), aeronautics, railway transport (diesel locomotive), electronic technology, defense production and many others.

An innovative means of thin-walled elastoporous elements production got first Euro-Asian patent which is valid (besides Russia) on the territory of Azerbaijan, Armenia, Belarus, Kazakhstan, Kyrgyzstan, Tajikistan and Turkmenistan.

In the end of 2014 Samara scientists made an international application for this invention in the USA and Germany. Currently an answer from German patent bureau is being waited.

“One of the most complex tasks with which we come across by introducing innovative activity is getting income from scientific developments. The first step on the way to commercialize scientific projects is patenting. This is a long and labor-intensive process, but we have a row of achievements in this field. The university has made 17 international applications to the leading nations in production: the USA, Germany and China”, - Gennadii Shestakov, head of Innovations Support Office, comments. “The first in the university history American patent shows that our inventions can compete with foreign innovations at the highest level.”

Samara University has been known for its active scientific and research work for decades and due to this factor as well the university was included in the Federal programme of Russian Academic Excellence Project 5-100.

For reference

The use of acoustic and vibration protection cannot only extend the life of complex and expensive equipment, but make its exploitation more comfortable. That is why fundamental and applied research in this sphere to which the use of elements on the basis of metal rubber material is related is more and more required in many fields of mechanical engineering – production of transport, energy, automobile, metallurgy and petrochemical equipment as well as spacecraft units.

In July 2016 mechanical engineering holding of Sinara Group – JSC “Sinara-Transport Machines” turned to SU scientists with a suggestion to develop vibroinsulators for the newest Russian high-speed diesel engines. As a result project works were conducted in ONIL-1 of SU. It led to the creation of vibroinsulators of metal rubber for diesel locomotives. The first set of this innovation produce is already shipped to the customer and tested successfully in Yekaterinburg. Currently preparation of serial production is being done in ONIL-1.

One of the results of the university scientists in the sphere of protection of aviation and rocket and space technology from dynamic and vibroacoustic influences became the development of a new running path for international space station (ISS) in cooperation with RSC “Energiya” and Institute of Medical and Biological Problems of RAS. Training complex BD-2 is being used by astronauts not less than 5 hours a day, it is equipped with innovative system of vibration isolation that permits to eliminate dangerous

In the course of earth tests of ONIL-1 a unique test facility allowing endurance test, autonomous test and other types of tests as well as performing exercises of BD-2 trainer set in the system of vibroinsulation with the imitation of zero-gravity conditions was created. Since 2013 BD-2 complex with the system of vibroinsulation is in proper exploitation and is under flight test aboard of ISS.

The basis of scientific and practical school of dynamics and vibroacoustics of machines was laid in Samara (Kuybyshev) more than half a century ago. Today it is in the number of the most authoritative ones in the world and is a brand of Samara University.

Photo: Artyom Onoprienko

RU

RU  EN

EN  CN

CN  ES

ES